As facilities approach the end of their design lives, operators of offshore platforms, subsea facilities, pipelines, onshore facilities, offshore wind farms, or solar parks may find that ‘Life Extension’ becomes an issue of increasing significance. Frequently, the present operating company may not even be the original builder and owner.

This raises many new challenges to which legislating bodies have responded by requiring a structure management system be applied to operating these facilities in order that fitness to operate during the period of extended life can be clearly demonstrated.

EPConsult Energies (EPEn) has developed a new ‘Work Practice for Life Extension Assessment’ that supports our experienced engineers and Clients in performing robust Life Extension Studies. Our Work Practice informs good quality decision making, thus enabling optimum CAPEX and OPEX investment and full life asset planning. See also OPEX Reviews.

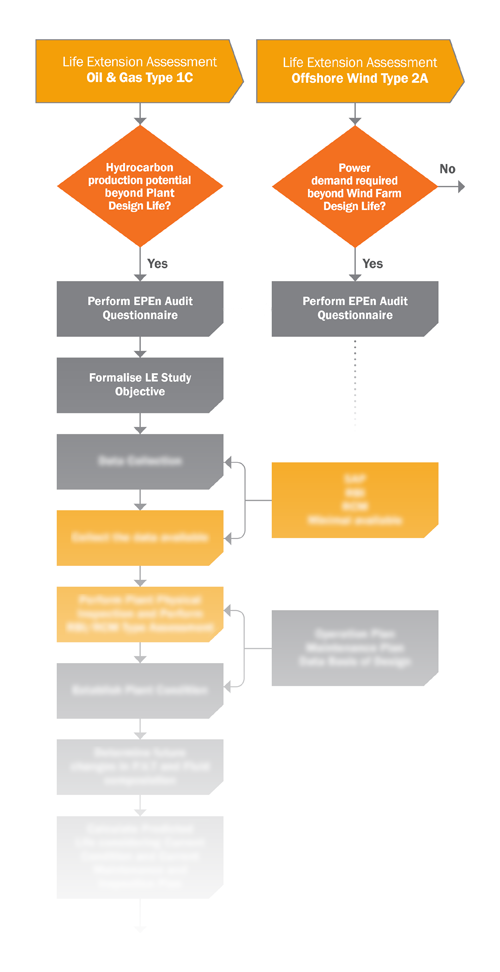

A Life Extension Assessment is a process whereby the engineering, construction, history, and mode of operation of selected critical items of platform equipment are examined together with the culture and practices of the organizations responsible for Asset Integrity Management. The Assessment is conducted in two stages. Stage 1 – Remaining Life Assessment - determines which components or systems are reaching the end of their service life. Stage 2 - Life Extension - evaluates the technical and commercial options for ensuring that the facilities can meet the extended life requirements of the owners and operators.

Life Extension Assessment is performed mainly using information supplied by the head office and site-based teams. Providing this data is available and accessible, the process should not require detailed inspection of equipment. Judgments are made focusing on longer-term operational sustainability rather than the short-term integrity or reliability status. In the absence of inspection and condition data, Life Extension Assessments will require a baseline inspection and condition monitoring prior to the study work.

EPEn can support you in determining the best strategy for your Life Extension Assessment, including what is the most applicable Life Extension methodology and what data should be obtained prior to initiation of the process. The initial consultation is free of charge and aims to add immediate value by focusing at costs and benefits.

The judgments in a Life Extension Assessment provide a balanced view of the anticipated actions and costs required to keep the equipment operational at an adequate level of integrity for the expected lifetime of the assets. In considering the impact of equipment sustainability on operations, the methodology addresses reliability, supportability, obsolescence, and maintainability.

Some equipment will require higher levels of maintenance expenditure due to known problems of proximity to end of working life or obsolescence. In situations where items may require replacement, costs are provided for like-for-like replacement. Typically, no process enhancements will be included unless requested by the Client.

The Life Extension Assessment will identify areas of concern on critical equipment where it can be expected that the life will not extend to the expected life of the field/park/platform. Thus, significant maintenance expenditure over and above the normal requirements will be identified.

Recommendations for improvement of work processes, as well as for maintenance or replacement investment in equipment, will be provided by our expert Asset Life Assessment consultants, experienced in the design, construction, maintenance, and operation of similar facilities.

For more information, you may wish to contact us at enquiries@ep-consult.co.uk or give us a call.

Case Studies:

ADGAS, UAE: Remnant Life and Life Extension Procedure.

EPConsult Energies (EPEn) has supported ADGAS in developing a procedure for the management of Remnant Life and Life Extension, for its LNG and LNG support-facilities on Das Island.

CNOOC, South China Sea: Life Extension Study for ageing Jacket Platform.

EPEn is preparing a Life Extension Project for offshore platforms, which involves application of RBI and RCM assessments.

DONG O&G, North Sea: Pipeline and Subsea Facilities Remaining Life and Life Extension Assessment.

Remaining Life and Life Extension Assessment for Siri Fairway: EPEn performed a Remaining Life and Subsea Life Extension Assessment to identify and estimate costs for all technical and operational issues that might be required to keep the production system in safe operation for a desired life extension.

ZADCO, UAE: Obsolescence Crane Replacement Study – Applying Value Engineering.

The challenge was to select the optimum engineering, transportation, installation, SIMOPS, maintenance and operations solution for replacement of ageing/obsolete cranes, that would reveal the best value for money. The Solution: Applying the Value Engineering methodology, the optimum solution was derived, identifying significant risk and cost reduction in the implementation phase.