EPConsult Energies has a wealth of expertise in performing Reliability, Availability and Maintainability (RAM) analyses for onshore and offshore projects.

We have performed RAM Analysis studies for many different types of projects, including:

- Onshore oil and gas treatment plants

- Cooling water systems

- Refineries

- Production platforms

- Pipeline systems

- Subsea production systems

- Integrated subsea production systems, risers, umbilicals, FPSO and offloading system

The outcome of a RAM study is of significant value. It can, depending on the timing of the study, provide:

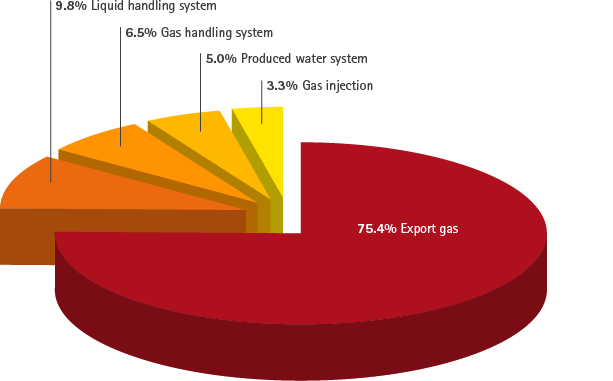

- Understanding of the most critical equipment and systems in the plant via Criticality Analysis

- Understanding of optimum redundancy approach

- Optimisation of spares holding

- Insight into how logistical delays can be improved

- Input to maintenance and integrity management – please also see Asset & Operational Studies

- Input to CAPEX and OPEX decisions

RAM analysis is typically used to predict the performance of the processing-production system and to provide a basis for production efficiency and production optimisation. In the conceptual phase of a project, RAM may support the conceptual selection process and, subsequently, can inform FEED and detailed design decisions. Generally, a complex process facility is divided into a number of subsystems. Those facilities identified as having the greatest influence on unavailability can be investigated in more detail, and design/operational/maintenance modifications may be recommended to optimise performance.

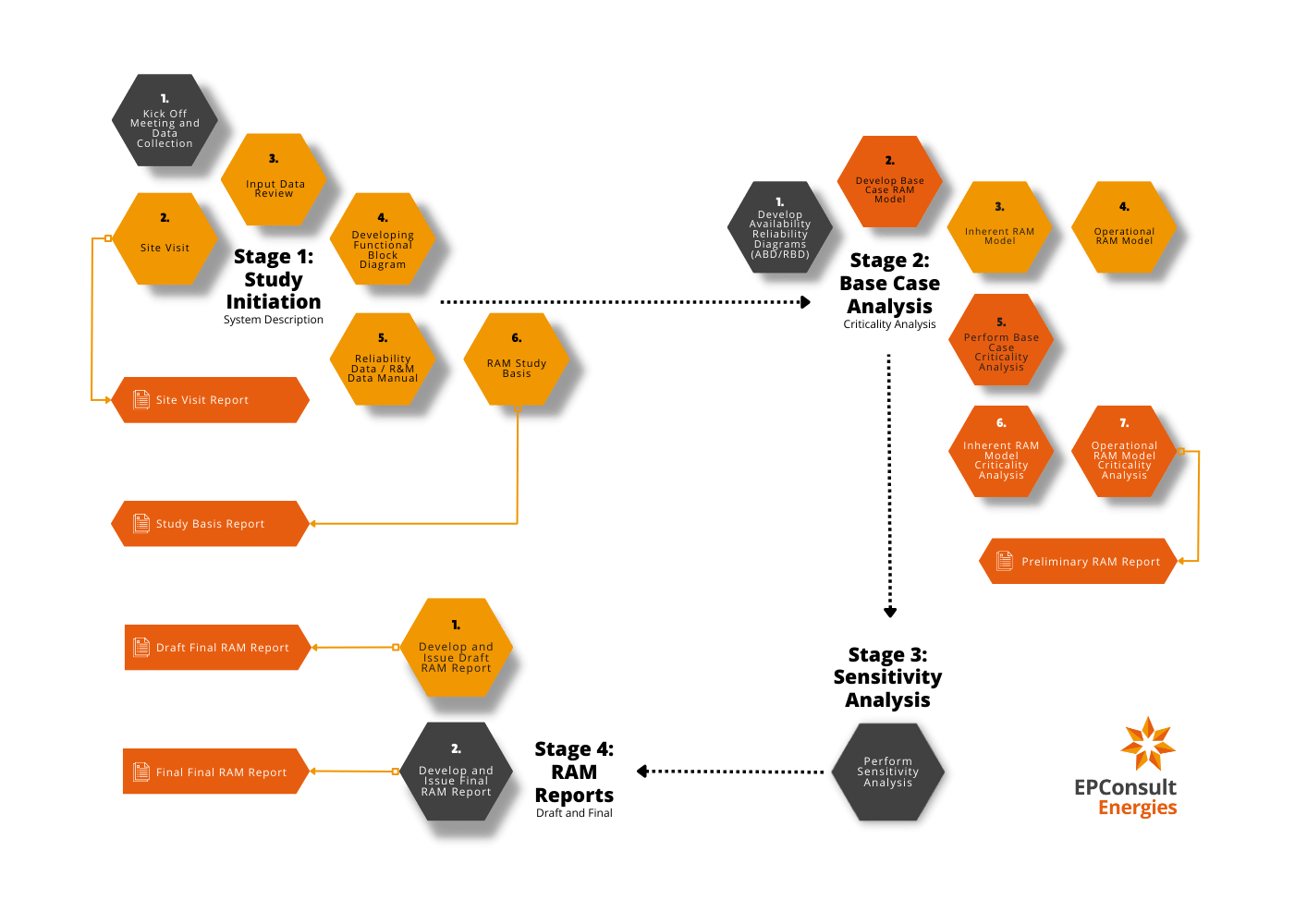

We use commercial software for performing RAM analysis, using Monte Carlo simulations and other analytical methods. Analytical methods for RAM analysis make the simplifying assumption that failure and repair times are exponentially distributed. Monte Carlo methods allow any probability distributions to be used to describe failure and repair times; and allow the consideration of more complex interactions between the system components. The Monte Carlo approach involves repeatedly sampling failure and repair times from the selected probability distributions. The performance of the system over many lifetime cycles is simulated to obtain a statistical estimate of system reliability and availability. RAM Studies involve the preparation of Functional Diagram and the definition of Reliability Block Diagram/Availability Block Diagrams.

We are able to link RAM analysis with process simulation. In this way we deal with situations where part of a system might go down and a reduced throughput can be calculated and taken into account in the availability computation. By considering the varying production profile over the field life, we can analyse the production efficiency of the system. Production efficiency may take into account production optimisation, production boosting, buffering, through-life reservoir depletion, and product sales. We can model all components from the reservoir through to the delivery point.

To discuss your specific requirement you may contact us at enquiries@ep-consult.co.uk

Case Study Example:

Our comprehensive RAM brochure provides detailed insights into how we deliver tailored solutions across various project stages, from concept to late-life operations. Learn about our methodologies, success stories, and how our team ensures peak performance for energy and industrial projects worldwide. Download our RAM Brochure to explore the full scope of our expertise and how we can support your projects.

Have questions or need tailored advice? Our experts are here to help.

Reach out to us via email at info@ep-consult.co.uk or call us directly at

+44 (0)20 7582 5555 (London) or +45 5359 3555 (Copenhagen).

We look forward to collaborating with you!