Hazard Identification Study (HAZID)

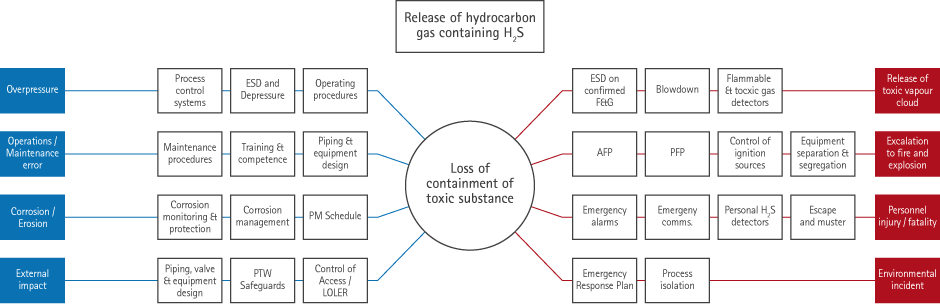

EPConsult Energies (EP) has completed numerous complex Hazard Identification studies for various clients across multiple industries. Our proven approach facilitates multidisciplinary workshops to systematically identify and rank Major Accident Hazards (MAH) to personnel and the environment.

Our comprehensive HAZID process includes:

- Documentation of safeguards for each identified MAH

- Assessment of residual risks

- Implementation of further risk reduction measures and action plans

Environmental Aspects Identification Study (ENVID)

Environmental Impact Identification (ENVID) studies serve a critical role in identifying potential environmental hazards associated with proposed developments and project scopes. These comprehensive assessments establish acceptable remediation strategies to contain associated environmental risks within acceptable regulatory and operational limits.

Hazard and Operability Study (HAZOP)

Hazard and Operability (HAZOP) represents a systematic, industry-standard approach for identifying potential operational threats. Our HAZOP methodology reviews process safety designs and evaluates operational reliability across oil and gas operations, chemical plants, and nuclear facilities.

Our HAZOP review process examines piping and instrumentation diagrams (P&IDs) using primary and secondary guidewords to systematically describe deviations from design intent.

HAZOP Study Components

- Flare and relief systems analysis

- Batch operations evaluation

- Cause and Effect Charts development

- Interlock Systems assessment

- Start-up and Shutdown procedures review

Safety Integrity Level Study (SIL)

A Safety Integrity Level (SIL) Study provides critical analysis of Instrumented Protective Functions (IPF) to ensure systems are appropriately designed to handle the worst-case consequences of foreseeable control system failures.

Our SIL assessment process determines appropriate Safety Integrity Levels for each IPF through structured workshop environments, utilizing either Layers of Protection Analysis (LOPA) or Risk-Graph methodologies.

SIL Verification Process

SIL verification occurs during the detailed design phase and encompasses comprehensive reliability analysis of IPF architecture, combined with optimized testing and inspection intervals. Our verification approach applies either Fault Tree Analysis (FTA) or advanced simulation techniques to verify that IPF reliability results successfully achieve the required SIL level specifications.